Our Business

HOME > Our Business

Since the company establishment in 1988, SKK has been conducting the cleaning services of storage tanks of oil refineries, power generation plants, tanker vessel, and various kinds of pipelines. Then in 2004, SKK totally took over its tank business of our parent company at that time, Taiho Industry who developed COW, Crude Oil Washing first in the world and went into the business of tank cleaning in a full-scale.

COW processing is a standard method now in the world for de-sludging of accumulated sludge in large scale crude oil tanks with safe, short period and inexpensive manner.

SKK has put its full effort on improvement of COW technology to standardize it as SKK-COWS as well as diversification into related cleaning services such as pipeline cleaning. Our cleaning services has got high-level client evaluation to satisfy their requirements in oil and other industries because of advanced performance rating and top HSE degree.

In 2010, SKK became a 100% subsidiary of Daiseki Co., Ltd., who stands as a leading company of Recycling and Environment business in Japan, and plays a part of Daiseki group companies at present.

While crude oil is stored in oil storage tank for a long time, hard crude oil sludge must be accumulated on the bottom of tank. Crude oil sludge mainly consists of wax, asphaltene, heavy oils, water and inorganics. Properties and generation amount of the sludge may vary depending on the type of oil and the storage conditions, and it may accumulate up to 5m high in tank in some cases and cause those problems as the reduction of storage capacity of the tank or the inclination of the floating roof tank in a terrible case.

By law in most of the countries, storage tanks for hazardous materials such as crude oil are regularly required to open for internal inspection, and to do so, all the sludge in tanks shall be discharged and completely cleaned before inspection.

The issue of crude oil sludge treatment is big and longtime concern both for oil producers and refiners because of its nature and problems of huge cost, long downtime period and awkward conventional desludging works.

Under those circumstances, SKK has been providing sludge treatment services as an expert with forty (40) years’ experience for large scale tanks of crude oil and heavy fuel oil. SKK still pays continuous efforts to develop technologies for cleaning methods, washing machines and processing facility to recover valuable oil products, which results in the first-class reputation for the technology and performance not only in Japan but throughout the world.

SKK-COWS Unit

SKK-COWS Unit Installation of COW Unit and Equipment

Installation of COW Unit and Equipment Tank Inside View after COW Cleaning

Tank Inside View after COW Cleaning Preparation Work on Tank Roof

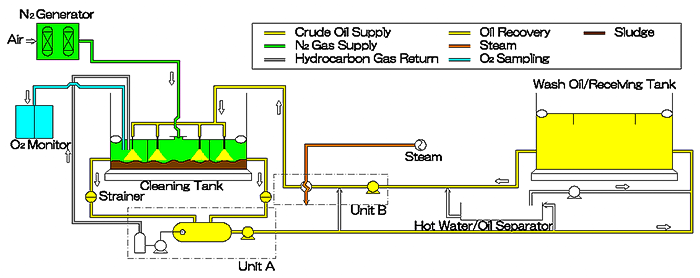

Preparation Work on Tank RoofSKK-COWS (Crude Oil Washing System) has been established as a standard desludging method for large scale crude oil tanks in Japan and applied to a lot of clients in the world.

SKK-COWS, no-man-entry with full mechanical method is the most economical and practical technology which meets customer requirements of desludging with short term schedule, full oil recovery and HSE satisfaction.

Nitrogen(N2) gas from N2 generator unit is injected into the cleaning/target tank to secure non-explosion condition to less than 8% Oxygen(O2) content in the tank, where flammable gas is filled. Crude oil from the wash oil tank is pressurized and jetted onto the sludge in tank through jet washing machines to dissolve the sludge. This washing operation is so-called “Jet Washing in Gas Phase” which means the remaining crude oil in the cleaning tank is removed to another crude oil tank beforehand in order to bare the sludge surface in gas phase and then the jet flow directly hits the sludge in tank. Direct jetting is so efficient to break the sludge that more than 98% of sludge can be dissolved in a short period.

Sludge conditions are different from each project case because of the amount of sludge, sludge property, etc. SKK has an enormous amount of know-hows due to a long time experience of more than 40 years, which enables us to take up difficult cases, for example discharge of the sludge piled on more than 10M high in tank.

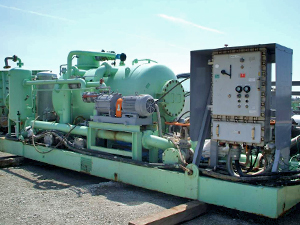

SKK provides SKK-COWS units, skid-mounted and vehicle transportable type units and jet washing machines with training service.

Manufacturing of SKK-COWS Unit

Manufacturing of SKK-COWS Unit

Training Course of SKK-COWS

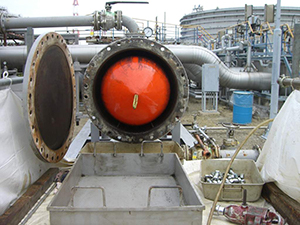

Training Course of SKK-COWSCleaning by pig is good for inside cleaning of pipeline, especially those pipelines of long distance, underground, subsea, large diameter, multi-bent, .. ..

Upon selecting suitable pig and pig running method determined by the conditions of cleaning object, for example, dirty or rusty condition, the distance and etc., we insert pig(s) in the pipeline and run it for cleaning. The driving force of pig running is air or liquid which may be solvent or wash fluid.

Arrival at Pig Catcher

Arrival at Pig Catcher Pig Insertion to Pig Launcher

Pig Insertion to Pig LauncherIt is internal washing of pipeline by high pressure water/hot water jet, which is good for bent piping. Jet washing for various pipeline sizes are available by corresponding jet nozzles.

Jet Washing by Water

Jet Washing by Water After Jet Washing

After Jet Washing Cutting Work for Preparation

Cutting Work for PreparationVarious kinds of waste water such as hot water washing after COW, cleaning or equipment test water can be treated properly.

Treatment processes at site are:

Typical treatment facility is Pre-coat type filtering, which shows high performance by the combination of activated charcoal and filtration for oily waste water. It enables the treatment of large volume waste water with inexpensive cost and limited area.

This facility is widely used to treat oily waste water after COW operation especially for the clients who do not have the facility of waste water treatment in their sites.

Facility of Pre-Coat type Filtration

Facility of Pre-Coat type Filtration Temporary tank of Waste Water

Temporary tank of Waste WaterSKK is engaged in installation and maintenance works for process pipeline, transportation line, firefighting pipeline, and other pipelines for power plant, chemical plant, oil&gas plant, and other plants.

SKK provides the following services for various kinds of tanks.

Inspection after Cleaning Works by COW

Inspection after Cleaning Works by COWLarge amount of hydrocarbon vapor is discharged to the atmosphere at COW operation or by other works in the case of tank opening. SKK VOC Recovery facility is to treat the evaporated gas and purify outlet gas to the atmosphere. Its adsorption process is available for most of hydrocarbon vapor discharged from oil & gas and coal plants by selecting suitable activated charcoal in the facility.

VOC Gas Recovery Facility

VOC Gas Recovery Facility

SKK plays a cooperative role in transportation and treatment of industrial wastes and hazardous wastes as a member of Daiseki group companies.

SKK sells jet washing machines for COW operation, which have been developed by the joint efforts with machine manufacturing company. The machines are not only for COW operation but cleaning of any kinds of tanks.

Jet Stream Test with Water

Jet Stream Test with Water AMW Jet Washing Machine

AMW Jet Washing MachineThe features of AMW Jet Washing Machines are:

RJM Installation on Tank Bottom

RJM Installation on Tank Bottom

RJM

RJMRJM, Rotary Jet Machine is installed on the bottom zone of crude oil tank to prevent sludge accumulation, for which large amount of crude oil is jetted from RJM nozzle for total agitation in tank. As shown in the following picture, crude oil pipeline from the pump outlet is installed in the tank to connect RJM which revolves horizontally by fluid energy and jets large amount of crude oil.

RJM Running Scheme, Two RJM Installation Case

RJM Running Scheme, Two RJM Installation Case

Yokkaichi logistic center is located in the central Japan to store SKK-COWS units, variety of equipment, materials and consumables for tank cleaning activities.

The roles of here is:

It is critical function to mobilize thousands kinds of equipment/materials/goods required for the project quickly to the site without shortage/delay. Yokkaichi logistic center plays the role of such functions for successful projects. SKK can provide the equipment and materials in Yokkaichi Logistics Center as a rental basis.